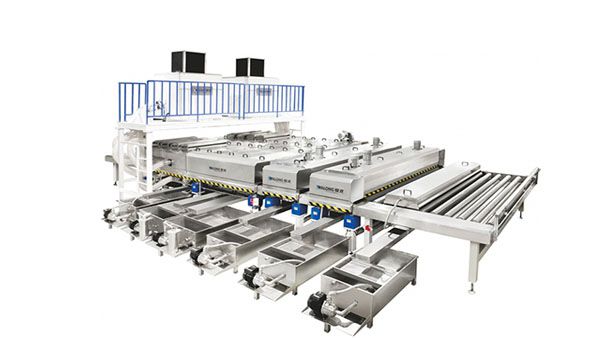

High-End Configuration Glass Washing and Drying Machine for Low-E Glass

Yalong H series horizontal glass washer is a washing and drying machine that comes with high configurations for guaranteed glass processing performance, the washing speed is up to 12m/min. Especially designed for processing low-E glass, this horizontal glass washing machine is able to rinse glass thickness from 3mm to 25mm, and up to 3600mm in either width or length. In order to ensure the high cleaning quality, high stability and long service life, we adopt 304 stainless steel machine construction, supreme variable-frequency drive motor, full- vulcanized rubber roller and Mitsubishi operation system.

| Model | Max. Glass | Min. Glass | Glass Thickness | Working Speed |

| 3600mm | 450*450mm | 3-25mm | 0-15m/min | |

| 3300mm | 450*450mm | 3-25mm | 0-15m/min | |

| 3000mm | 450*450mm | 3-25mm | 0-15m/min | |

| 2500mm | 450*450mm | 3-25mm | 0-15m/min | |

| 2000mm | 450*450mm | 3-25mm | 0-15m/min | |

| 1600mm | 450*450mm | 3-25mm | 0-15m/min | |

| 1300mm | 300*300mm | 3-25mm | 0-15m/min |

-

- Excellent washing and drying quality

-

- 1. The glass feed end is equipped with a pre rinse section and independent water tanks to preliminarily clean the glass surface.

- 2. The washing and rinsing section is built with three pairs of roller brushes and water tanks for thorough glass cleanness. Among the brushers, one soft brush is for washing low-E glass, driven by an independent variable frequency motor.

- 3. The drying section adopts three pairs of air knives to dry rinsed glass surfaces.

- 1. The glass feed end is equipped with a pre rinse section and independent water tanks to preliminarily clean the glass surface.

-

- Simple operation and easy use

-

- 1. PLC system with touch screen for ease of operations.

- 2. High-quality variable-frequency drive motors allow for auto adjustment of working width and working speed according to the glass size.

- 3. Hot air device shortens the drying time.

- 4. External water tanks are built with wheels for easy removal and cleaning. Water filters are equipped.

- 1. PLC system with touch screen for ease of operations.

-

- Reasonable design

-

- 1. Air knives of the unique design can effectively lower the noise level to below 85dB (within 1 meter of the machine)

- 2. Waterproof machine cover is made of 304 stainless steel. Seams between machine cases are tightly sealed by seal strips to prevent water.

- 3. Water tanks are mounted above the drying section with frequency conversion fans.

- 4. Auto lift of upper bracket for ease of maintenance.

- 1. Air knives of the unique design can effectively lower the noise level to below 85dB (within 1 meter of the machine)

-

- Energy conservation and high durability

-

- 1. Aluminum upper bracket profile: strong, durable and robust

- 2. Special design of air knifes ensures the drying quality and reduces energy consumption.

- 3. Wear-resistant full- vulcanized rubber rollers

- 4. The machine side plate is made by 304 stainless steel for higher durability

- 1. Aluminum upper bracket profile: strong, durable and robust

If you have questions about our products or want to request a quotation, please feel free to contact us at any time.

As a glass processing machinery manufacturer, Yalong mainly focuses on developing and manufacturing glass washing and glass grinding machines that are made to fit different glass fabrication applications. We do not only provide glass manufacturers and glass processing facilities with glass machinery, but also support worldwide customers in the field of glass working to enhance their glass production efficiency, product quality and energy saving. Thanks to our long period of engagement in the glass processing industry, we acquired professional expertise and in-depth knowledge to provide the precise glass processing solution for your glass production application. No matter whether your need is glass washing or glass grinding, Yalong can help you select the appropriate glass processing equipment that well suits your glass manufacturing needs.